Technology

Carboniq Clean is a revolutionary cleaning and surface preparation solution utilizing recycled CO2. This technology swiftly and efficiently removes contaminants from plastic, composite, and other surfaces. Our Carboniq Clean solution offers a dry cleaning process that serves as a sustainable alternative to aqueous cleaning. Enjoy substantial energy savings, improved yields, and the elimination of drying times and additional chemicals. Prepare surfaces for painting and bonding at a fraction of the cost compared to traditional methods.

About CO2 Composite Spray

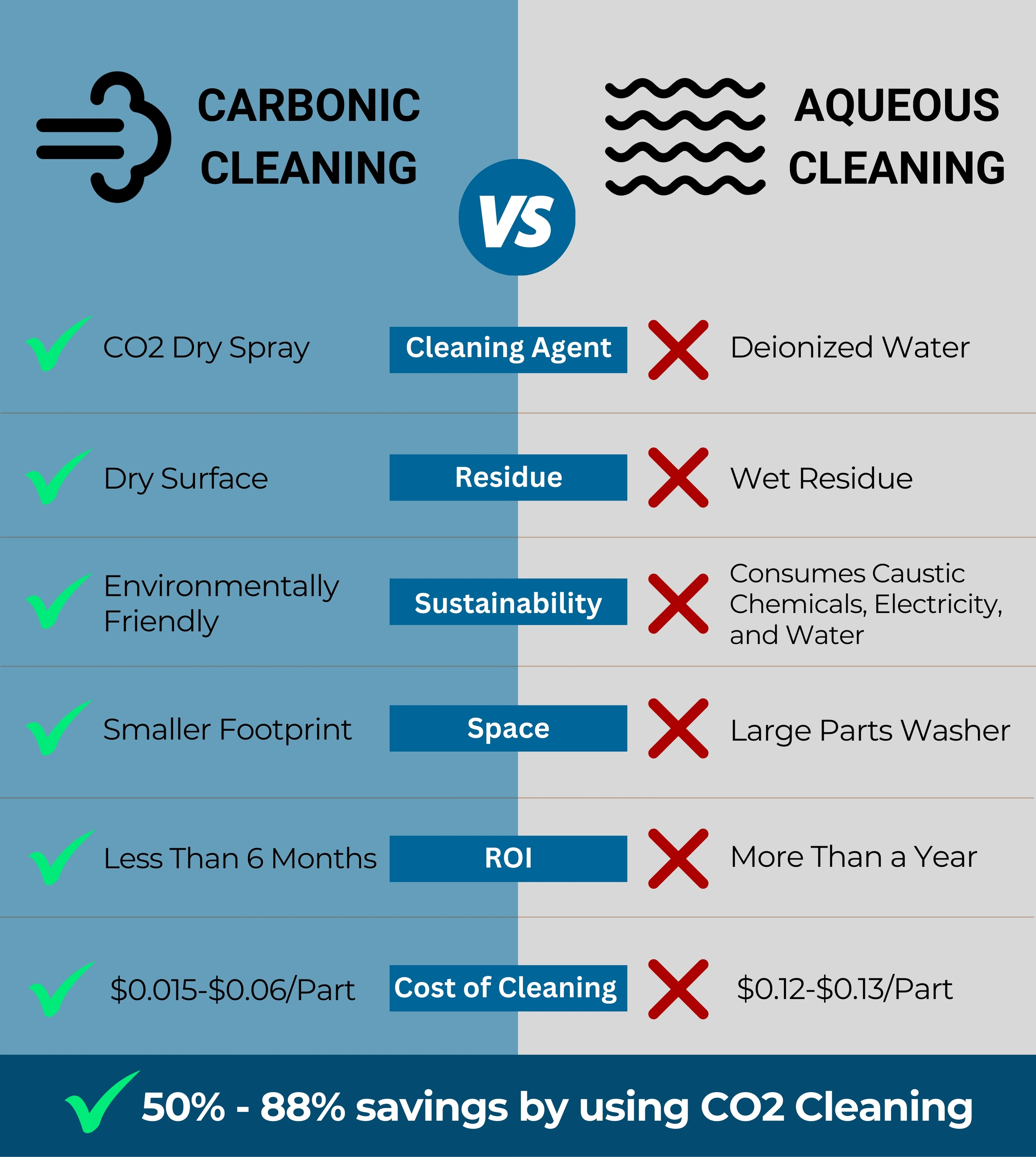

CO2 and aqueous cleaning are two different methods used for cleaning various surfaces, they involve different cleaning agents and processes. Here are the key differences between the two:

-

Cleaning Agent:

-

CO2 Cleaning: In CO2 cleaning, carbon dioxide micronized particles are used as the cleaning agent. These particles are accelerated at high speeds and impact the surface to be cleaned, removing contaminants through a combination of physical and chemical cleaning actions.

-

Aqueous Cleaning: Aqueous cleaning involves the use of water-based cleaning solutions. These solutions may include detergents, surfactants, and other chemicals to facilitate the removal of contaminants.

-

-

Residue:

-

CO2 Cleaning: CO2 cleaning is considered a dry process, meaning it does not leave any liquid residues behind. The carbon dioxide sublimates (turns directly from a solid to a gas) upon impact, leaving a dry surface.

-

Aqueous Cleaning: Aqueous cleaning may leave a wet residue, depending on the cleaning solution used. Which requires an energy intensive rinsing and drying process.

-

-

Environmental Impact:

-

CO2 Cleaning: Dry cleaning is generally considered environmentally friendly since it uses solid CO2, which is a byproduct of other industrial processes.

-

Aqueous Cleaning: Most aqueous cleaning solutions contain chemicals that require proper disposal.

-

-

Cost of Cleaning:

-

CO2 Cleaning: The cost of CO2 cleaning is relatively lower, ranging from $0.015 to $0.06 per part. The use of solid carbon dioxide particles is efficient, and the process often requires less maintenance compared to other cleaning methods, contributing to cost-effectiveness.

-

Aqueous Cleaning: Aqueous cleaning may have a higher cost per part, typically ranging from $0.12 to $0.13. The costs can vary based on the type of cleaning agents used, the complexity of the cleaning process, and the need for additional steps such as drying. Aqueous cleaning systems may require more maintenance and consume more resources, influencing the overall cost.

-

Dry CO2 vs Aqueous Cleaning

How Carboniq Clean Works

Superior Surface Preparation

CO2 cleaning has demonstrated notable effectiveness in achieving superior surface finishes, taking into account both Ra (Roughness Average) and Rz (Maximum Height) parameters, when contrasted with aqueous cleaning conducted under the same conditions. The dry and non-abrasive nature of CO2 cleaning contributes to its effectiveness, potentially resulting in smoother surfaces. Ra, representing the average surface roughness, may benefit from the non-abrasive qualities of CO2 cleaning, while Rz, reflecting the maximum height difference, showcasing a reduction in extreme variations. This comparison underscores the potential advantages of CO2 cleaning in achieving enhanced surface finishes, making it a notable consideration in applications where surface quality is paramount.