Products

Carboniq Clean's CO2 composite spray technology combines the cleaning power of microscopic crystals of liquid carbon dioxide with patented coaxial jet spray cleaning processes to effectively remove contaminants (i.e., particles, thin films, heat) from exterior or exposed surfaces of a product.

Carboniq Clean

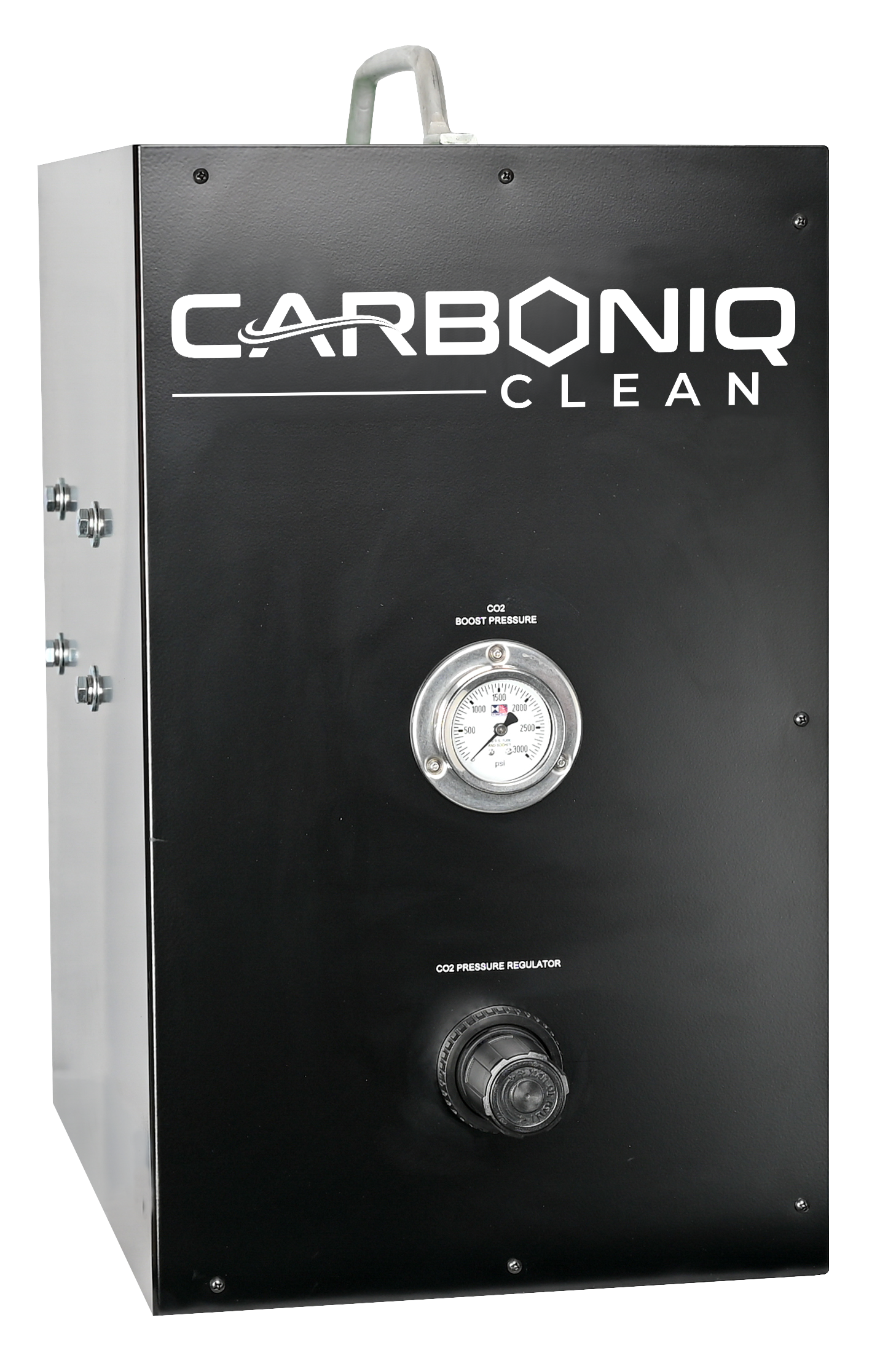

Transfer System

Our Transfer System ensures a continuous supply of high-pressure CO2 from a low-pressure source (around 300 psi), stored in a temperature-controlled ASME-rated stainless steel tank. This system incorporates dual pneumatic pumps and automated maintenance scheduling. Our Transfer Pump system converts industrial CO2 into high-quality liquid CO2 (99.99% purity) for precision cleaning. There are two configurations: Standard (0.5-micron filtration) and Ultra (0.003-micron filtration).

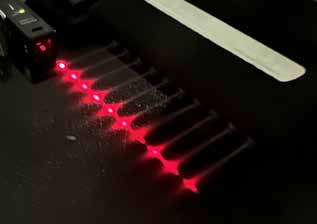

Laser Monitoring

Our CO2 Spray Quality Monitoring Technology comes equipped with advanced Process Fluid Smart Sensor Packages. This comprehensive system includes features such as:

-

Provides important quality metrics regarding CO2 spray particle-air compositions in real-time. Analogous to using electrical conductivity to determine deionized water (DIW) quality – laser light monitors the chemistry of a CO2 Composite Spray™. The laser light detects changes in spray composition such as propellant pressure and CO2 injection rate (spray particle density).

-

Assures reliability of the CO2 spray cleaning process in real-time.

-

Informs the production operator:

-

The spray is operating within its established cleaning process window

-

The spray composition has changed.

-